Balmoral

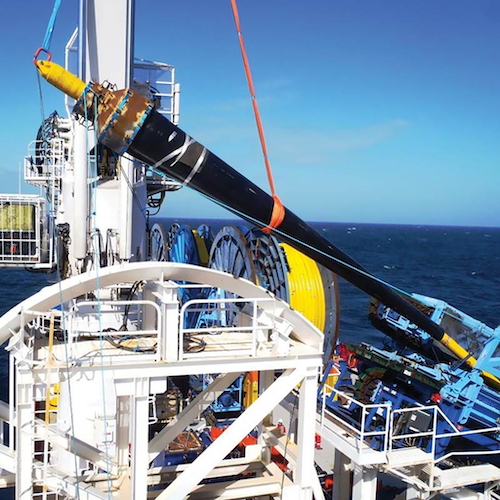

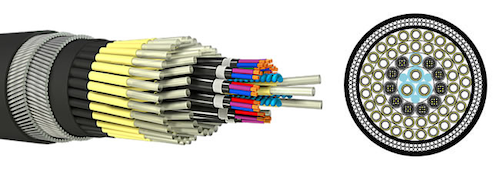

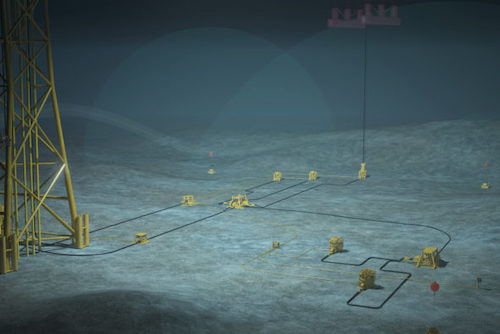

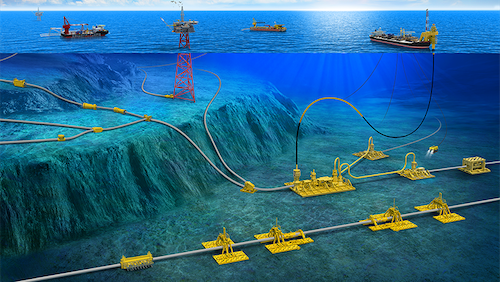

Balmoral is the acknowledged market leader for buoyancy, insulation and elastomer product solutions including drilling and distributed riser buoyancy, thermal insulation, cable protection, bend restrictors, stiffeners and riser protection guards.

The company’s purpose-built production facilities, subsea test centre, R&D continuous improvement programme, experienced HSE, engineering and commercial departments all play their part in delivering safe and successful projects time after time on a global basis.Installers and operators are seeking to deploy the latest technology to achieve efficiencies throughout the life of a project. With almost 40 years’ experience Balmoral is strongly positioned to advise clients on their subsea challenges.

Balmoral Offshore Engineering